Heat transfer devices transfer heat between two or more fluids while keeping them separate. They are essential in various industrial and domestic applications, such as HVAC systems, power generation, refrigeration, and chemical processing. By facilitating the transfer of heat, they ensure efficient energy use and optimal system performance.

Various types of heat exchangers exist, each designed for specific purposes and working conditions. The most common types include:

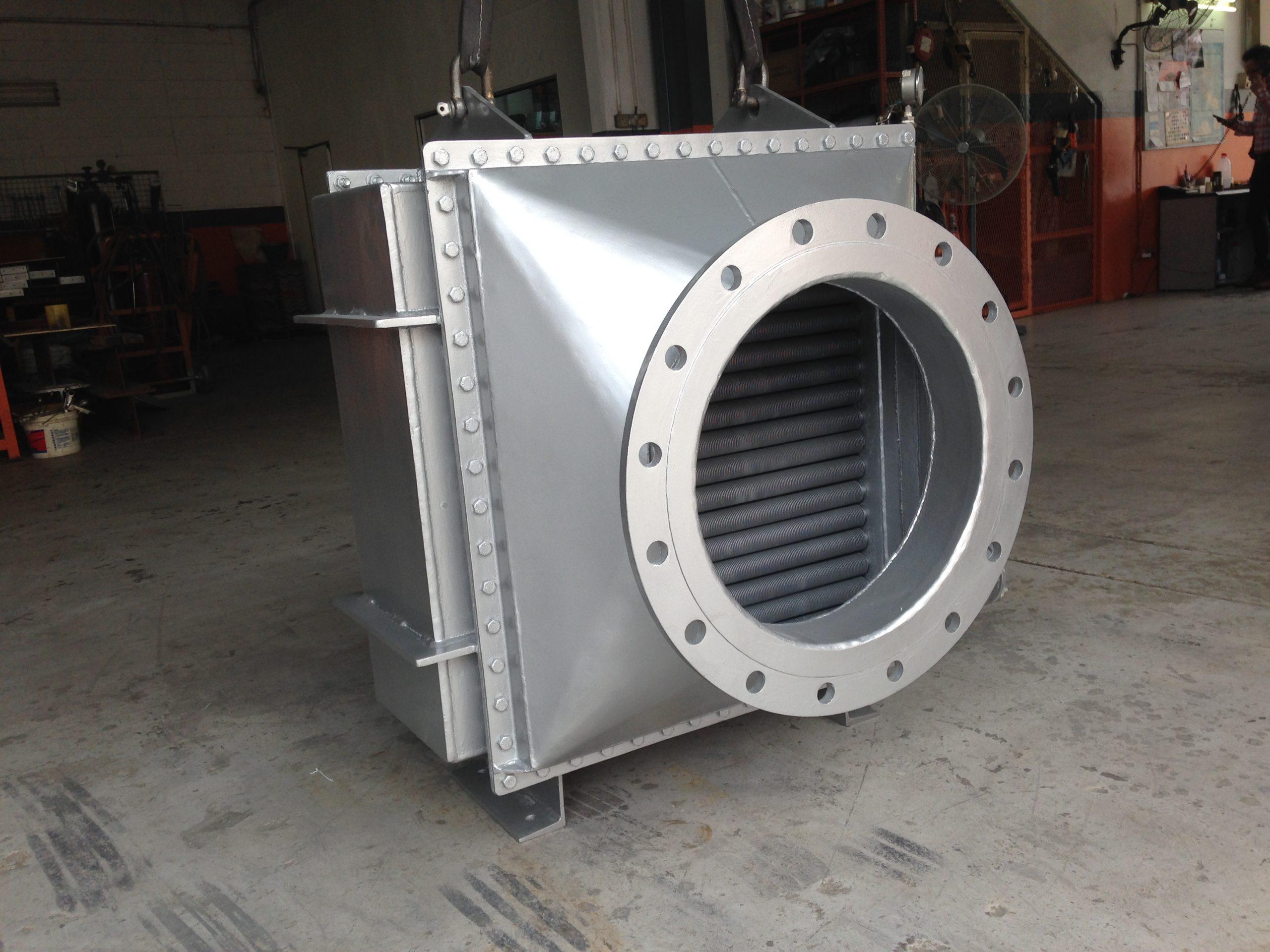

Shell-and-tube heat exchangers: These have a series of tubes enclosed in a cylindrical shell. One fluid flows through the tubes, while the other flows around them within the shell. This setup facilitates effective heat transfer and is frequently used in power plants and oil refineries for high-pressure situations.

plate heat exchanger-type heat exchangers: This design features thin, corrugated metal plates stacked together for heat transfer. Fluids pass between alternating plates, optimizing the surface area for heat transfer. Plate heat exchangers are compact, efficient, and easy to maintain, making them popular in HVAC, refrigeration, and food processing systems.

plate heat exchanger-type heat exchangers: This design features thin, corrugated metal plates stacked together for heat transfer. Fluids pass between alternating plates, optimizing the surface area for heat transfer. Plate heat exchangers are compact, efficient, and easy to maintain, making them popular in HVAC, refrigeration, and food processing systems.

Air-cooled heat exchangers: These use air to cool or heat a fluid. Air is blown over tubes containing the fluid by fans, facilitating heat transfer without using water or other cooling liquids. These are often used in industries where water is scarce or unavailable.

Double Pipe Heat Exchangers: These consist of two concentric pipes, with one fluid flowing through the inner pipe and another through the annular space between them. They are generally used for smaller applications and are appreciated for their straightforward design.

Heat exchangers work based on heat transfer through conduction. One fluid transfers thermal energy to another fluid through a solid barrier, such as the walls of the pipes or plates. The fluids do not mix as they never come into direct contact. For example, in a car radiator (a type of air-cooled heat exchanger), hot coolant from the engine passes through the radiator’s tubes, where heat is transferred to the surrounding air, cooling the fluid before it returns to the engine.

Heat exchangers are used in numerous applications across industries. They are crucial in power plants for electricity generation, chemical plants for temperature control in reactions, and refrigeration systems for air cooling. They are also widely used in HVAC systems to regulate indoor temperatures in homes, offices, and commercial buildings.